Additional info: PDF file COLD ROLLING - right click save as

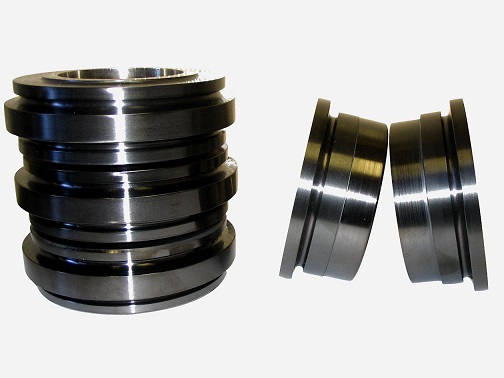

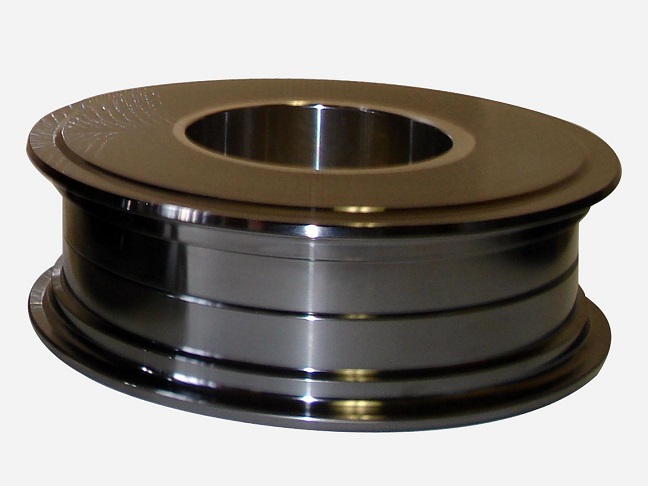

DLC - Diamond Like Carbon coating for Cold Rolling DLC - An excellent coating for cold rolling operations, including flat, foil and ring rolling, roll bending, roll forming and profile rolling. The main benefit of DLC coating is eliminating galling solution on mating surfaces solution, which is often a problem. DLC helps to solve problems with defects of end-products surfaces, like lap, mill-sharing, rolled-in scale, scabs, seams and slivers. DLC coating treated tools provide highest precision because the coating is only microns thick. High performance of DLC coated rollers is defined by combination of properties of DLC coating: high hardness, low coefficient of friction, inertness inertivity to any chemicals and elimination of adhesion of DLC coated surface to any metals. MAINTENANCE CYCLE - DLC coated rollers increase maintenance interval 4 to 5 times. - DLC coated rollers reduce maintenance cost drastically BETTER QUALITY OF END PRODUCT - DLC coated rollers enhance dimensional accuracy and surface quality of manufactured parts. ~ UNIFORM QUALITY is maintained during longer production runs PVD vapour deposition coating, Black diamond coating, PVD, vapour deposition, best plasma vacuum coating